Ship Hull Inspection in 1 Hour

Ship operators have long been plagued by expensive, slow, inaccurate, and dangerous manual assessment of ship hulls to meet Class Standards. Flying-in class society surveyors and engineers is costly and time consuming. Diving below a ship hull in busy ports puts divers in harm’s way and drives up costs due to loss adjustment expenses. The time-consuming and subjective nature of traditional ship hull inspections translates to higher costs and less than optimal customer experience. More recently, drone-captured data has been utilized to improve safety and deliver a more cost-effective ship hull assessment, however, third-party position systems can take hours to setup, the drone data can take hours to process, and reports hours to compile and format, eliminating the ability to make decisions while the inspector is still on-site.

Download this guide to discover how to:

Increase safety by avoiding diver inspections and minimizing on-site personnel.

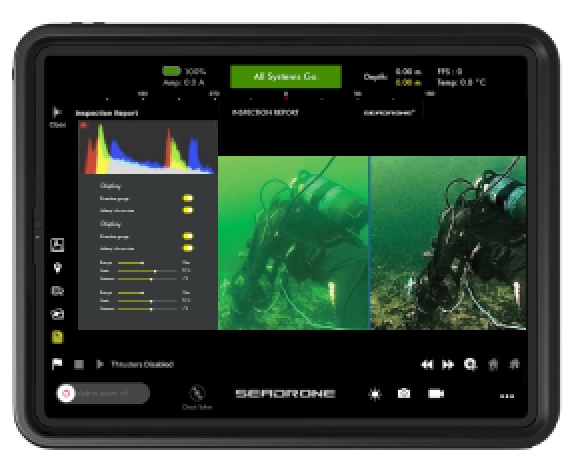

Improve the customer experience with transparency and faster inspections.

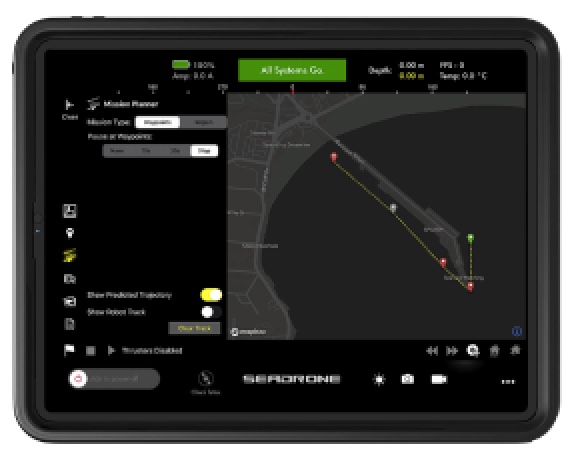

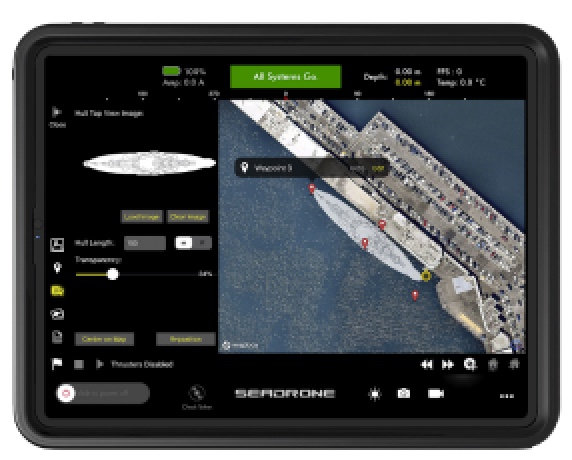

Collect more accurate data and create reports on-site in less than 1 hour.