SHIP HULL INSPECTIONS IN ONE HOUR

August 18, 2020

The biggest superhighway in the world is not made of concrete and dominated by freight trucks; it covers 70 percent of the globe and is plied by container ships. The antibiotics that form penicillin. The corn in breakfast cereal. The woodchips used to make your favorite book. Many of our daily essentials and conveniences depend on the shipping industry. But for all the attention given to the products transported above the water, what keeps the ship functioning efficiently is beneath the surface: the ship’s hull.

Today the company launches its latest underwater drone: the SeaDrone PRO and The Certified 1 Hour Ship Hull Inspection Solution. In this article and the below illustration, we break down the main differences that set SeaDrone apart from human diver inspections and other underwater Remotely Operated Vehicle (ROV) ship hull inspection methods.

Classification societies, or class societies, such as the American Bureau of Shipping (ABS) review essential ship services through the development and application of industry standards. Surveyors are employed by class societies to certify compliance with these standards. Efficient ship hull inspections make a surveyor’s job much easier and ensure the entire compliance process goes more smoothly. By maximizing uptime and ensuring their vessels are always functioning well out at sea, cutting inspection time from ten hours to one hour can be of huge benefit to ship operators. (Read more about the general benefits of ROV ship hull inspections before diving into the benefits of the new SeaDrone PRO.)

SeaDrone PRO 2020

“ An inspection process that used to take ten hours now only takes one. “

Time and Cost Savings / Comparison Table

How does SeaDrone cut inspection times to one hour? Put simply: a faster, safer, more accurate process. The secret is a fast and frictionless workflow that begins with setting the acoustic-based positioning system and ends with annotated real-time data compiled into PDF reports. The sensors on the vehicle are tightly integrated and the output data is formatted to best suit the surveyor reviewing the report.

In the past, surveyors mostly conducted ship inspections onsite. Now remote surveys – or Remote Inspection Techniques (RIT) - are gaining popularity, notably with industry leaders Remote Steaming and Recording, DNV GL, RINA, Lloyds Register, and the Bureau Veritas. Imagine automating routine hull inspections so your field teams can focus on putting their expertise to work and enabling coordinators to take quicker decisive action. With SeaDrone , the inspector can stream live video from the underwater vehicle to a surveyor, who logins remotely via the “SeaDrone LIVE” feature to supervise and ensure the inspection is performed according to class standards. This cuts travel costs, travel time, and waiting time.

Ship hull inspections can be broken down into three stages: the inspection experience, data collection, and decision-making. Below we take a closer look at each stage. These are also depicted in the illustration below.

THE INSPECTION EXPERIENCE

Scheduling and mobilizing divers, obtaining permits from a port authority, and scheduling a class society surveyor can all be time-limiting factors when it comes to ship inspection preparation. SeaDrone removes all of these limiting factors by streamlining inspections to surveyors and other engineers. No need to schedule a specially trained ROV pilot when SeaDrone is ready-to-use right out of the box. The intuitive SeaDrone Software design crucially lowers the point of entry for ROV piloting.

The first step once a diver or ROV is in the water is to orient themselves relative to the ship, which is often easier said than done.

The diver method: When divers are used for ship hull inspections, a ship operator must do the proper planning to schedule diver time. Permits must also be obtained from the port authority for docking, often for extended periods of time if the divers need more time in the water. A class society surveyor must also be scheduled ahead of time. This can be time-consuming and dependent on the various schedules of the divers, port authority, and surveyor.

During diver deployment, the ship engines must be disabled before a dive group can begin their work. The water current must be below one knot for the divers to conduct their work. A diver visually locates himself, but this can be difficult in bad sea conditions, and compass navigation is subject to human error. (Read more about why it is faster and cheaper to use ROVs rather than human divers).

Other ROV inspection: The planning required for most ROV inspections includes scheduling a class society surveyor and printing out a physical copy of the ship general arrangement diagram to mark the inspection route of the vehicle. This latter step in particular can be a hassle and add valuable time to the preparation process.

An ROV normally establishes a position system and is manually navigated by a pilot to the ship’s hull, but this can be a lengthy step depending on the speed of the position system calibration and the skill of the ROV pilot.

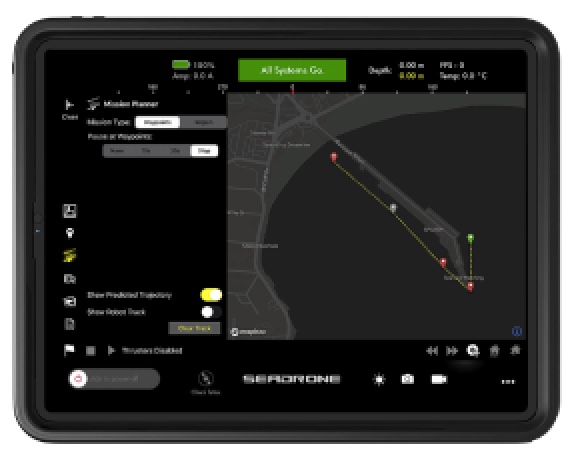

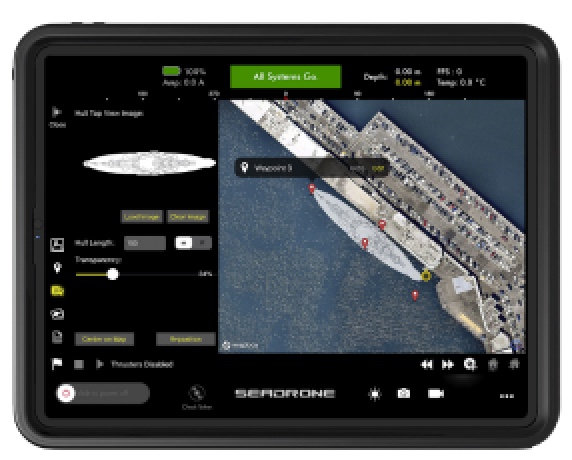

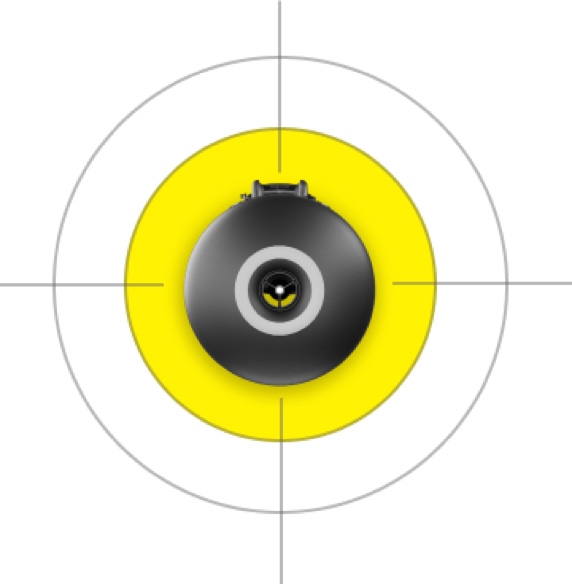

SeaDrone: A key to SeaDrone’s success is the shortened sensor set-up time. The SeaDrone app walks users through a setup all consolidated on the app, without a need to print a ship general arrangement diagram. Inspection is streamed to surveyors – who may login remotely – and other engineers. The SeaDrone method calibrates the SeaDrone PRO vehicle with a SeaDrone Sphere (learn more about the SeaDrone Sphere Locator) that quickly positions the vehicle relative to the ship. A pre-dive checklist is completed to ensure the inspection is safe and compliant.

DATA COLLECTION

Ship hull inspections consist of visually documenting various waypoints of the hull. How easily each waypoint is located and how quickly visual information can be collected from each waypoint determine the efficiency of the data collection.

The diver method: Divers take photos of the ship hull and note hull conditions manually. This depends on the dexterity of the divers and the visibility of the underwater conditions.

Other ROV inspections: Most ROV inspection methods involve a specially trained ROV pilot or multiple operators who direct the robot to collect photos and videos at waypoints. Photos and videos are visible in their final annotated format only after the robot has returned to the surface.

SeaDrone: The SeaDrone vehicle flies autonomously between waypoints, negating the need for a specially trained pilot who could delay the navigation process. Weighing in at less than 10kg, the SeaDrone vehicle is self-powered and easy to deploy by a single operator. Navigating around the ship is simplified by importing the map of the vessel. Before you had hands on a joystick; now the vehicle can be operated within the SeaDrone app which allows you to annotate visual data in real-time while the vehicle is still submerged and holding its position. The photos and videos are reviewed by the surveyor within the SeaDrone app running on the surface.

DECISION-MAKING

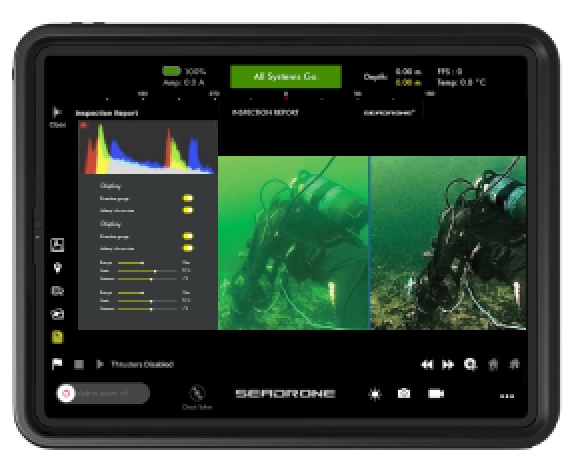

Ship hull inspection data is consolidated into a report that is reviewed by the surveyor to make sure the ship adheres to class society standards. This report can also be used by the ship owner or operator and by the inspector to make decisions about which areas on the ship hull require more attention. A faster decision-making process gives inspectors, surveyors, and ship operators the option to do more frequent and tailored inspections.

The diver method: Notes taken manually by divers must later be transferred to a report, which invites the possibility for human error and takes valuable time. The report takes longer to reach the hands of those who need to review it.

Other ROV inspections: Most ROV inspection methods copy and download photos, then manually process data once the ROV has returned to the surface to create a report. This data is shared with the ship operator and engineers. Later off-site decisions can be made, which adds time.

SeaDrone: Most inspection methods require the manual processing of data but SeaDrone removes that possibility for error to near zero. SeaDrone automatically generates PDF reports using the data you collected: such as photos, UT, CP, and laser measurements and augments the value of this data using your annotations and localization information. This provides a more holistic view of the inspection and facilitates on-site decisions.

The following table outlines the key performance qualities and outcomes of each of the three processes discusses. While using ROVs is significantly safer than using divers, only SeaDrone automated ship hull inspection system delivers consistent, high quality data without the need of a trained inspector.

“A faster, safer, more accurate process”

ABS

SeaDrone at Manzanillo / How do you perform your ship hull inspection?

“The intuitive SeaDrone Software design crucially lowers the point of entry of ROV piloting.”

Bureau Veritas / The ability to decide remotely

“Inspection is streamed to surveyors and your engineers who may login remotely.”

Digitally imported blueprint of a ship into SeaDrone’s app map to create a more detailed report.

“Weighing in at less than 10kg, the SeaDrone vehicle is self-powered and easy to deploy by a single operator.”

SeaDrone Underwater Inspection

Performance

A GAME CHANGER

Diver inspection methods can be subjective, dangerous, and costly. Traditional ROV methods can be rigid, inefficient, and inaccurate. The SeaDrone method is fast, accurate, and safe by offering superior software and streamlined processes.

ROV set-up takes about five minutes, the hull inspection itself lasts about 10 minutes per 100 meter section, and the processing of the PDF report with geotagged photos and videos takes about one minute. This keeps a ship hull inspection of even the largest ships at 400 meter length under the one hour mark.

COMMON THRUSTED PLATFORM

SeaDrone is bridging the gap between shipping companies, regulatory agencies, insurance companies, ship coating companies, and ship leasing companies, among others. SeaDrone is looking to become the de facto platform for ship hull inspections - trusted by insurers and regulatory agencies, needed by shipping operators, and saving both time and money.

THE SHIP OPERATOR’S CHALLENGE AND THE SEADRONE SOLUTION

Imagine docking your ship and within an hour completing the ship hull inspection process, without extra time spent planning or hiring external expertise. That is the future of ship hull inspections, and SeaDrone is leading the way.

SeaDrone has developed a solution that enables you to go beyond diver operations and perform class certified Underwater Inspections in lieu of Dry Docking. We have designed an end-to-end hull inspection solution that can inspect a vessel in one hour and create a certified report that can be quickly shared with your stakeholders. Collaborate with classification surveyors and your cross-disciplinary team in real-time while saving on travel time and travel cost using the SeaDrone LIVE remote streaming feature.

All this gives you greater control over your business. Because of the minimized downtime, you are able to perform inspections more frequently and plan for maintenance that minimize your dry dock time and prevent costly damage and disruption.

The intuitive SeaDrone design lowers the point of entry for ROV pilots, removes the risk of middleman human error in data transfer, and allows for on-site decision-making.

SeaDrone has been improving its underwater drones for more than a decade. Ship operators have previously used SeaDrone robots to perform quick spot inspections, but the data was not able to be class society certified without more accuracy and an expertly trained inspector. Now, with the release of the Certified 1 Hr. Ship Hull Inspection Solution, SeaDrone is changing that. SeaDrone’s solution offers a frictionless workflow from setting the acoustic-based positioning system to annotating real-time data compiled into PDF reports. SeaDrone’s end-to-end system which includes a custom-designed vehicle, patented acoustic localization system, proprietary navigation software, remote streaming service, and automated reporting ensure accurate data collection and the best user experience. Now surveyors can use SeaDrone to do full ship hull inspections, quickly and efficiently.

Read more about the latest SeaDrone at SeaDronePro.com

“The SeaDrone method is fast, accurate, and safe by offering superior software and streamlined processes.”

“That is the future of ship hull inspection, and SeaDrone is leading the way.”

Stay Dry. Ultimate Safety. Maximum Productivity.